Clean water is essential for human health, but unfortunately, access to clean water is not always guaranteed. According to the World Health Organization (WHO), 2.2 billion people lack access to safe drinking water, and approximately 842,000 people die each year from diseases caused by unsafe water, inadequate sanitation, and poor hygiene practices. One way to address this issue is through the use of membrane filtration technology. Hollow fiber ultrafiltration (UF) membrane filtration is a popular method for purifying water and other liquids. This technology uses a semi-permeable membrane with tiny pores to filter out impurities and contaminants. In this article, we will explain how hollow fiber UF membrane filtration works, its applications, and advantages.

The Basics of Hollow Fiber UF Membrane Filtration

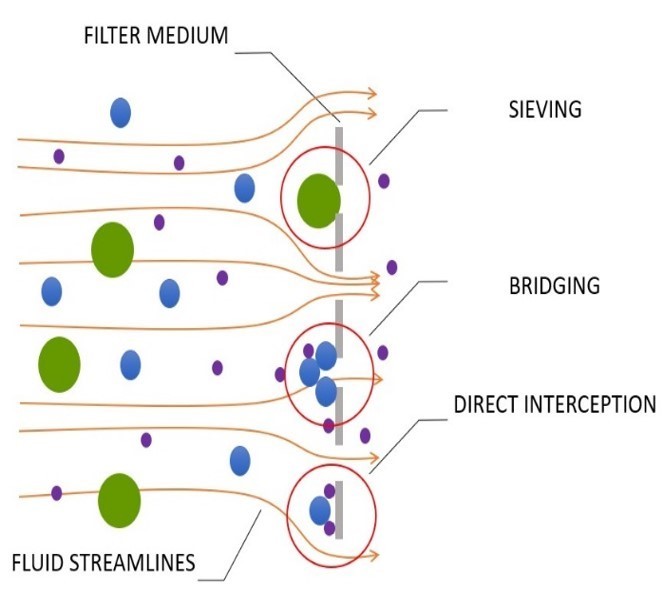

Hollow fiber UF membrane filtration is a process that uses a bundle of hollow fibers to filter out impurities in liquids. The hollow fibers are made from a semi-permeable membrane that has tiny pores. The size of the pores can be adjusted to filter out specific contaminants based on their size. Typically, the pore sizes are in the range of 0.01 to 0.1 microns.

The molecular weight cut-off (MWCO) is another essential parameter that determines what size particles can pass through the membrane. The MWCO is the molecular weight of a particle that is retained by the membrane. UF membranes have MWCOs in the range of 1,000 to 500,000 Da.

The liquid to be filtered is forced through the hollow fibers under pressure. The liquid flows through the pores in the membrane and leaves behind the impurities. The purified liquid passes through the membrane and is collected on the other side. The hollow fibers used in UF membrane filtration are incredibly thin, typically less than a millimeter in diameter. They are bundled together to create a large surface area for filtration. The increased surface area allows for higher flow rates and more efficient filtration.

How Does Hollow fiber UF Membrane Filtration Work

Hollow fiber UF membrane filtration can be operated in two modes: dead-end filtration and cross-flow filtration.

Dead-end Filtration

In dead-end filtration, the liquid to be filtered is passed through the hollow fiber membrane in a single pass. This mode of filtration is suitable for small-scale applications, but it is not practical for large-scale operations as the membranes become clogged quickly, leading to reduced filtration rates.

Dead-end filtration reduces pumping demand by eliminating the need to recirculate retentate, lowering the amount of operational energy required. For liquids with low particle loads, dead-end filtration is frequently used. To maintain low flux rates and allow the filtration cake to form on the surface under higher particle loads, membranes with a high surface area can be used. To prevent a deeper buildup of particulate matter, the velocity of the feed flow and the surface area of the membrane must be carefully designed and controlled. Failure to provide a sufficient amount of surface area can result in a deeper buildup of particulate matter, higher transmembrane pressures, and even irreversible fouling of the membrane.

Dead-end filtration is a common operating preference in ultrafiltration and is commonly used to treat surface waters or as a pre-treatment stage for subsequent treatment processes.

Cross-Flow Filtration

In cross-flow filtration, the liquid to be filtered is passed tangentially along the surface of the membrane, and a portion of the liquid is forced through the membrane. This mode of filtration is more efficient than dead-end filtration as it reduces membrane fouling by removing the impurities from the surface of the membrane.

After reaching a crossflow velocity, the force of the retentate flow prevents particulate buildup on the membrane surface. Trans-membrane pressures are reduced and batch runs can be extended by removing the build-up.

Crossflow filtration systems are frequently used in batch processes as well as for more complex and difficult feed streams. Microfiltration in a crossflow configuration is an excellent product clarification method that is widely used in breweries, wineries, and the production of cider, vinegar, and fruit juices.

Because of the energy requirements for achieving crossflow velocity, only a limited amount of surface area can be installed while maintaining acceptable operational expenditure (OPEX) values over the system’s lifecycle. Crossflow membrane units have a smaller surface area, which means there are fewer lumens to drive the process stream through, resulting in higher velocity at lower flow rates.

Applications of Hollow Fiber UF Membrane Filtration

Hollow fiber UF membrane filtration is commonly used to purify water in both industrial and residential settings. It is particularly effective at removing contaminants such as bacteria, viruses, and other microorganisms that can cause illness. The following are the major applications of hollow fiber UF membrane filtration:

1. Drinking Water Treatment

Hollow fiber UF membrane filtration is widely used for the treatment of drinking water. The technology is highly effective at removing impurities such as suspended solids, bacteria, viruses, and other microorganisms. In addition, it can also remove dissolved organic matter and other contaminants that affect the taste and odor of water. UF membrane filtration is often used as a pre-treatment step for reverse osmosis (RO) membrane filtration, which removes dissolved salts and other contaminants from water.

2. Wastewater Treatment

Hollow fiber UF membrane filtration is also used for the treatment of wastewater. The technology is effective at removing suspended solids, bacteria, and viruses from wastewater. UF membrane filtration can be used as a pre-treatment step for RO membrane filtration, which removes dissolved salts and other contaminants from wastewater.

3. Food and Beverage Production

Hollow fiber UF membrane filtration is also widely used in the food and beverage industry to remove impurities from liquids such as juices, milk, and beer. It can be used to remove suspended solids, bacteria, and other contaminants that can affect the taste, appearance, and safety of the product.

The technology can also be used to concentrate liquids such as fruit juice or whey protein. By removing water from the liquid, the concentration of the product can be increased, making it more economical to produce.

4. Biotech and Pharmaceuticals

In the biotech industry, hollow fiber UF membrane filtration is used to purify proteins, enzymes, and other biological molecules. The technology is particularly useful for separating molecules based on their size and charge.

The technology is also used in pharmaceutical production to purify drugs and other compounds. By removing impurities and contaminants, the purity and efficacy of the drug can be improved.

Advantages of Hollow Fiber UF Membrane Filtration

Hollow fiber UF membrane filtration offers several advantages over other filtration technologies. For one, it is highly effective at removing impurities and contaminants, including bacteria and viruses. The technology is also versatile and can be used to purify a wide range of liquids.

Another advantage of UF membrane filtration is that it is a physical process that does not require the use of chemicals. This means that it is environmentally friendly and does not produce harmful byproducts.

UF membrane filtration is also cost-effective compared to other filtration methods. The technology is easy to scale up, and the membranes can be reused for extended periods, reducing operating costs.

Final Words

Hollow fiber UF membrane filtration is a highly effective and versatile technology for purifying water and other liquids. The semi-permeable membranes with tiny pores allow for the filtration of impurities and contaminants, including bacteria and viruses. The technology has numerous applications in industries such as food and beverage, biotech, and pharmaceutical production. UF membrane filtration is cost-effective, environmentally friendly, and produces no harmful byproducts. However, the membranes can become fouled over time, reducing their effectiveness, and require periodic maintenance. Overall, hollow fiber UF membrane filtration is a valuable tool for providing clean and safe water and liquids for human consumption and industrial applications.