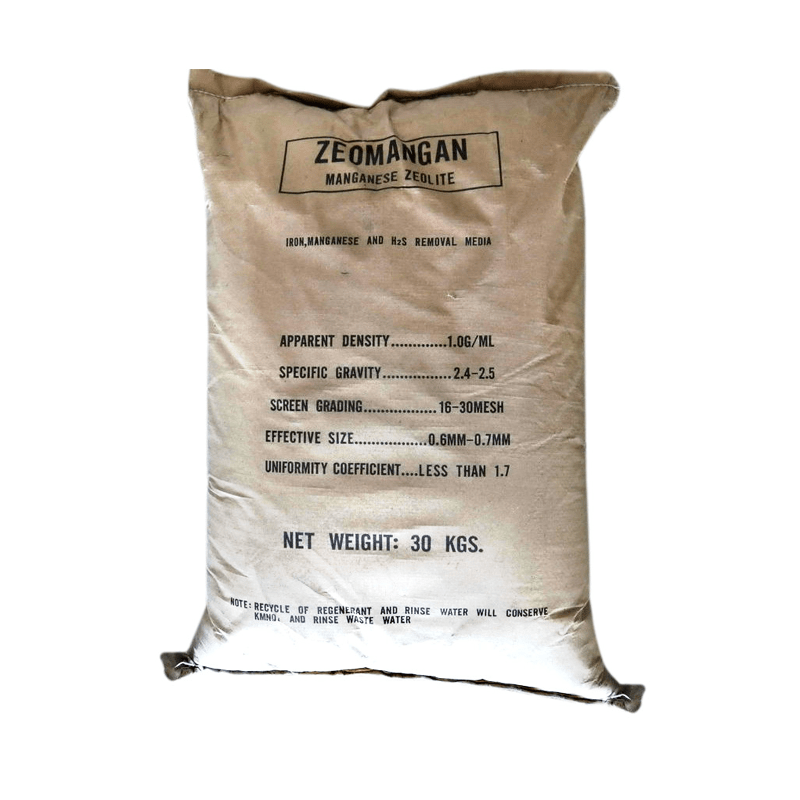

General Description of MANGANESE ZEOLITE

MANGANESE ZEOLITE, used for removing soluble iron and/or manganese as well as hydrogen sulfide from well water supplies. It is a purple-black filter media processed from ceramic zeolite granules. Zeomangan can be used in a completely closed pressure system with no aeration or pumping, or in an open gravity filter system. The most common method of operation is continuous regeneration, which is recommended for predominantly iron water.

PHYSICAL CHARACTERISTICS

| Apparent density : | 1.0 g / ml |

| Shipping weight : | 30 Kg / 30L |

| Specific gravity : | 2.4 ~ 2.5 |

| Screen grading (dry) : | 16 ~ 30 mesh |

| Effective size : | 0.65 + 0.05 mm |

| Uniformity coefficient : | Less than 1.7 |

| pH range : | 6.2 ~ 8.5 |

| Maximum temperature : | 25 C |

| Maximum pressure drop : | 0.85 kg / cm2 |

| Backwash rate : | 40 ~ 50 m / hr |

| Service flow rate : | 5 ~ 12 m / hr |

| Minimum bed depth : | 70 cm |

METHODS OF OPERATION

* Continuous regeneration

Continuous regeneration operation is recommended for well water where iron removal is the main objective with or without the presence of manganese. Briefly, it involves the feeding of predetermined amount of potassium permanganate (KMnO4), usually in combination with chlorine (Cl2), directly to the raw water prior to the unit containing Zeomangan continuous regeneration. The chlorine should be fed upstream of the KMnO4 with a contact time of 10 ~ 20 seconds if possible. Sufficient chlorine should be fed to produce the desired residual in the filter effluent. Enough KMnO4 should be fed to produce a “just pick” color in the filter inler. The will maintain the Zeomangan media in a continuously regenerated condition.

The quantity of Cl2 and KMnO4 required can be estimated as follows:

mg / L Cl2 = mg / L Fe

mg / L KMnO4 = (0.2 * mg / L Fe) + (2 * mg / L Mn)

Without Cl2 the KMnO4 demand can be estimated as follows:

mg / L KMnO4 = (1 * mg / L Fe) + (2 * mg / L Mn)

SUGGESTED OPERATING CONDITIONS for MANGANESE ZEOLITE

- Backwash: Sufficient rate using treated water to produce approximately 30% bed

- Rinse: At normal service flow rate for 5 minutes or until the effluent is

- Capacity: 350 ~ 500 g/m2 of bed area based on potassium permanganate In addition to the

- Zeomangan continuous regeneration a 70 cm minimum bed of specially sized

- Zeomangan is required in any case the pressure drop should not exceed 70 ~ 0.85 Kg/cm2.

Reviews

There are no reviews yet.