Drinking water-related concerns in underdeveloped nations are caused by microorganisms from poor sanitation, which result in illness and diarrhea. This is due to the fact that many of these villages lack access to centralized water treatment facilities. User-friendly, low-cost, low-maintenance, and grid-independent point-of-use (POU) systems are significant options for treating water in poor communities.

They also treat and reduce the number of pathogens in water supplies, and many POU systems have been deployed and used by these communities, thereby improving their livelihood. This analysis focuses on POU systems that serve families or communities, with the goal of examining and evaluating technology used in POU systems over the last decade.

Water is necessary for life. It’s also a variety of anthropogenic operations like agriculture, laundry, and manufacturing. While practically everyone in the industrialized world has access to better drinking water, more than 30 percent of people in the least developed countries do not.

The WHO/UNICEF Joint Monitoring Program (JMP) method defines improved water sources as water from a piped network, tube wells, protected dug wells, springs, and rainfall collecting. Many people have had access to better drinking water sources in recent decades thanks to increased knowledge and advancements in water treatment and distribution.

More than 1.1 billion people acquired access to better drinking water sources between 1990 and 2005, with 83 percent of individuals having access to improved drinking water sources. However, an estimated 663 million people continue to drink untreated water from wells, springs, and surface water due to a shortage of adequate drinking water. Users will be prone to waterborne infections if they use an unimproved water source.

Water Treatment Plant Benefits

Public health: Water treatment facilities are necessary to remove pollutants, diseases, and toxins from water coming from a variety of sources. This prevents waterborne illnesses and improves public health by guaranteeing that the water used in homes and businesses satisfies safety regulations.

Environmental Protection: These plants are essential in preventing pollution of natural water sources. They protect aquatic ecosystems and biodiversity by processing wastewater from commercial, industrial, and residential sources to keep dangerous materials out of rivers and lakes.

Use in Industry and Agriculture: Water treatment is essential to the operation of both industries and farms. Utilizing treated water for agriculture, manufacturing, and other purposes promotes economic expansion and sustainable development.

Various Tyoes of Water Treatment Plant in Bangladesh

● Wastewater Treatment Plants (WTP): Wastewater treatment plants, or WTPs, handle both domestic and commercial wastewater. On-site wastewater treatment is essential for managing massive wastewater volumes in industries like paper manufacturing, chemical plants, and petroleum refineries.

● Sewage Treatment Plants (STP): Concentrate on purifying sewage waste and pollutants from both business and residential sources. STPs are frequently used in large cities to manage municipal sewage, guaranteeing a cleaner environment.

● Effluent Treatment Plants (ETP): These facilities treat industrial wastewater that contains significant levels of chemical pollutants, which is frequently encountered in industries like textile production and pharmaceuticals.

● Demineralization Treatment Plants (DM): These facilities purge water of dissolved particles, serving sectors including food service and electronics manufacturing that need extremely pure water.

● Reverse Osmosis Water Treatment Plants (RO): Often used in manufacturing, semiconductor production, and other industries, ROs use pressure to extract contaminants from wastewater.

7 Key Steps of a Water Treatment Plant

Water treatment is the process of getting rid of anything that could be physically, chemically, or biologically harmful to the water supply for household and human use. This process helps to produce of water that is secure, delightful, clear, transparent, and odorless. Additionally, water needs to be non-corrosive so that it won’t harm piping.

Large-scale water treatment for urban municipal water supply involves seven key processes. The article below describes each stage in detail.

1. Screening

Screens must be used to remove any large floating and suspended pollutants from the intake in order to protect the treatment plant’s main units and promote their effective functioning. These pollutants can damage machinery or restrict flow through the plant. They include leaves, twigs, paper, rags, and other garbage.

Screens come in coarse and fine types

Coarse Screens

Which are used to keep coarse materials (such logs and fish) out of the treatment plant, are constructed of corrosion-resistant steel bars spaced 5 to 15 cm apart. The screens are set up at a 60-degree angle to make mechanical raking of the gathered material easier.

Fine Screens

Following the coarse screens, the fine screens filter out anything that can block the plant’s pipes. They are made up of 5 to 20 mm-apart steel bars. The micro strainer is a kind of the fine screen that has a mesh size that ranges from 15 micrometers to 64 micrometers, or from 15 to 64 millionths of a meter. It is made of a revolving drum of stainless steel mesh. Plankton and algae, which are minute organisms that float with the stream in water, are examples of suspended materials that can be captured. High-pressure water jets using clean water are used to remove the trapped solids from the fabric and transport them for disposal.

2. Aeration

Following screening, the water is aerated (provided with air) by circulating it through a set of processes so that it can take oxygen from the atmosphere. This technique assists in eliminating any gaseous organic compounds that give the water an unpleasant flavor as well as soluble gases like carbon dioxide and hydrogen sulfide, both of which are acidic, making the water less corrosive. Aeration also eliminates manganese or iron by oxidizing them to an insoluble state. Iron and manganese can discolor clothes and give off-putting tastes. These chemicals can be eliminated via filtration after becoming unusable.

In some cases, too much algae in the raw water might lead to a development of algae that blocks the sand filter later in the treatment process. Pre-chlorination is the process utilized in these circumstances to destroy the algae instead of, or in addition to, aeration. This step in the water treatment process comes before the more important ones. Pre-chlorination also causes chemicals that give off a flavor or smell to oxidize.

3. Coagulation and Flocculation

Following aeration, coagulation occurs to remove the small, suspended particles (less than 1 m in size). In this procedure, water is mixed with a substance known as a coagulant, which has a positive electrical charge, neutralizing the negative electrical charge of the tiny particles. A high-speed impeller in a rapid mix tank quickly disperses the coagulant after the coagulant is added.

The tiny particles’ charges are now balanced, and they combine to form ‘flocs,’ which are soft, fluffy particles. Ferric chloride and aluminum sulfate are two coagulants that are frequently used in the treatment of water.

The following action is flocculation. Here, the flocs interact with one another to generate larger flocs as the water is gently moved by paddles in a flocculation basin.

As the water moves through the flocculation basin, the compartments are frequently divided into smaller ones with slower mixing rates. Increasingly huge flocs can grow in this divided chamber without being separated by the mixing blades.

4. Sedimentation

Once big flocs have formed, they must be settled out by a procedure known as sedimentation (when the particles fall to the floor of a settling tank). After coagulation and flocculation, the water is maintained in the tank for a number of hours so that sedimentation can occur. Sludge, the substance that has gathered at the tank’s bottom, is taken out and disposed of.

5. Filtration

The method of filtering involves removing particles from a liquid. Water is treated by running through sand and gravel beds to remove any solids that could not be separated in the sedimentation tank. Rapid gravity filters are frequently used, with a flow rate of 4–8 cubic meters per square meter of filter surface per hour.

The filters are back-washed when they contain a lot of trapped solids. When pollutants are trapped in the filter, clean water and air are forced back up the filter to release them, and the dirty water—known as backwash—is pumped into the sewer system, if one exists. Alternatively, after settling in a sedimentation tank to remove sediments, it may be released back into the parent river.

6. Chlorination

Following sedimentation, the water is disinfected to get rid of any pathogenic microorganisms that might still be present. The chemical used for disinfection that is most frequently used is chlorine, either as a liquid (such sodium hypochlorite, or NaOCl) or a gas. It is easy to use and reasonably priced. Chlorine reacts with any contaminants, including microorganisms, in water over a specific amount of time, known as the contact time, when added to the water. Residual chlorine is the quantity of chlorine that remains after this. Up until the water reaches the users, this remains in the water throughout the distribution system, guarding it against any microorganisms that might penetrate it.

According to World Health Organization guidelines (WHO, 2003), water should have no more than 5 mg of residual chlorine per liter. After 30 minutes of contact time, water should have a minimum residual chlorine content of 0.5 mg l-1 (WHO, n.d.). There are many techniques for purifying water (e.g., using the gas ozone or ultraviolet radiation). Still, once it has left the water treatment plant, these cannot keep it from becoming contaminated by germs. The cleaned water is then delivered into the distribution system after disinfection.

7. Supplementary Treatment

It can be necessary to provide additional care for the benefit of the general public. Fluoridating water is one example of this, which involves adding fluoride to water. The World Health Organization has said that “whenever practical, fluoridating water supplies is the most effective public health approach for the prevention of dental decay.” Around 1 mg of fluoride per liter of water is the ideal amount (1 mg l–1).

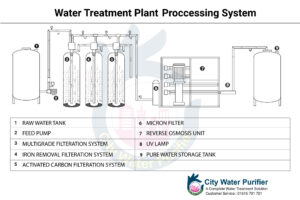

Water Treatment Plant (WTP) Process

A novel technology must have advantages over established treatment techniques in order to be considered. Lower capital and operating and maintenance expenses, more efficiency, easier operation, improved effluent water quality, and reduced waste output are just a few examples.

Nonetheless, a water treatment system must be proved in phases in order to be accepted and deployed at a big municipal scale.

Stage 1: Demonstration of success in a different field.

Stage 2: Benchtop and pilot-scale testing and development (1 to 50 GPM).

Stage 3: Demonstration-scale verification (>100 GPM).

Stage 4: Several successful installations and operations at a small scale (0.5 to 5 MGD).

Stage 5: Implementation at a large-scale municipal water treatment plant.

Each of the mentioned stages can take a long time to complete, depending on the technology being evaluated, how urgently it needs to be implemented, how long it takes for its cost to reach competitive levels, and the importance of its position in the overall water treatment train.

The final factor differs from the others in that it distinguishes between a technology proposed as an alternative to filtration, which is an important component of water treatment, and a technology proposed to replace a less important component, such as a pump, automation, chemical feed, taste-and-odor control, or peroxidation.

Water Treatment Plant Price in Bangladesh

Water treatment plant prices in Bangladesh vary depending on kind, size, and efficiency. Prices typically fall between 50,000 and 100,000 Tk. Price structures vary depending on the type of facility, such as reverse osmosis water treatment plants (RO), demineralization treatment plants (DM), iron removal plants, and effluent treatment plants (ETP). For example, a RO plant usually ranges between 100,000 and 200,000 Tk, whereas an ETP plant may range between 50,000 and 500,000 Tk.

Final Words

In Bangladesh, water treatment plants are essential to guaranteeing a sustainable and safe water supply. These facilities support both environmental preservation and population well-being by solving the problems and implementing creative solutions.

Now that you understand how crucial it is to filter wastewater, you should contact City Water Purifier, a reliable water treatment plant supplier in Bangladesh, to buy high-quality plants.